During a boiler service there are a number of parts that are checked in order to keep the boiler operating safely.

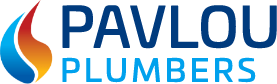

This 1st image is of a set of electrodes that are in a Worcester CDi Classic boiler. These electrodes are constantly in the flame when the main burner is on. The electrode on the left helps detect flame. If this electrode is to short and is not in contact with the flame the boiler will think there is a fault and cut off the gas supply to the boiler. The 2 electrodes on the right create the spark to ignite the flame. It’s important that the distance between them are as stated in the manufacturers instructions in order to operate correctly.

This next image is of a seal for a Glowworm boiler. The seal was attached to the flue which is responsible for getting rid of the emissions of the boiler. This caused products of combustion mixing with the air being sucked into the boiler from outside. In turn this meant the boiler was noisy and not performing properly at the cost of the customer.

If the seals in the picture above and below where left in the boiler they would become hard, brittle, and stop protecting the boiler by keeping the heat in the correct place. This gasket can be found in many Worcester boilers.

These parts do not always require changing every year. A lot depends on the level of use of the appliance and the quality of the parts. As can be expected the parts that are in the more expensive boilers tend to last longer.

To arrange a boiler service with Pavlou Plumbers please either call on 01244 888801 or email info@pavlouplumbers.com